Electrical discharge machining

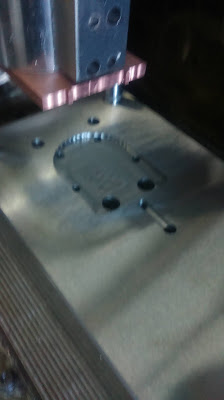

Electrical discharge machining (EDM) uses electrical discharge to remove material from blocks of metal and is also known as electro-discharge erosion.The basic process is really quite simple and can be very useful when considering different manufacturing methods for your design project.

An electrical spark between the electrode and metal is created

Due to the electricity flow the spark generates heat up to 8000 – 12000 degrees Celsius (damn hot). The spark however is very skillfully controlled and makes sure to only alter the very surface of the part. Because of this the composition of the material below the surface is not affected by the heat.

Wire EDM is another variation which is conducted while submerged in purified water (deionized). The water’s conductivity makes for a great dielectric environment for EDM. The purified water also works as a coolant and helps erode irregularities in the material.

For more information and all your EDM needs the team at ALNO are happy to help.

Contact ALNO